Container homes are no longer a fringe housing solution. In Washington State, where affordable housing and flexible construction alternatives are in growing demand, container homes are steadily becoming a viable, even preferred, choice for both homeowners and businesses. Their modern aesthetic, structural integrity, and cost-efficiency have earned them attention from architects, developers, and city planners. But the real question for many is: Does Washington actually allow container homes? The answer is yes—with the right planning and compliance with building regulations.

Washington is a progressive state when it comes to sustainable development, but that does not mean the process of placing a container home is universally simple. Because container dwellings sit at the intersection of residential, commercial, and sometimes industrial use, and because they use non-traditional construction methods, the regulatory pathway varies across counties and municipalities. Understanding how state codes interface with local requirements is essential to moving forward confidently with your container home project.

Why Container Homes Are Gaining Interest in Washington

The rise of container-based construction in Washington is no accident. For a state frequently challenged by rising land values, labor shortages, and housing constraints, container homes offer a faster, more affordable, and environmentally friendlier option. Whether for primary residences, accessory dwelling units (ADUs), emergency shelters, or mobile office spaces, these units are compact, durable, and relatively easy to customize.

Container homes also align well with Washington’s commitment to sustainability. They promote reuse of materials, can be designed for energy efficiency, and often require less site disturbance than traditional construction. Moreover, the modular nature of containers allows for phased development, which is appealing in areas where phased permitting or funding cycles are necessary.

Overview of State vs. Local Jurisdiction

The first key to understanding container home legality in Washington lies in the state’s governance structure. The state establishes the general building code framework through the Washington State Building Code Council (SBCC), which adopts and amends national model codes like the International Building Code (IBC) and the International Residential Code (IRC). These codes serve as the minimum legal standard across Washington.

However, enforcement and additional zoning regulations are left to local municipalities—cities and counties. That means while container homes may be allowed under state code, each local jurisdiction can create its own planning rules, impose additional design requirements, or establish restrictions based on neighborhood character, historical overlays, or infrastructure limitations.

Therefore, a container home might be approved in unincorporated King County but face hurdles in downtown Seattle unless you meet strict urban design criteria.

Washington State Building Code (WCC) & International Codes

Washington has adopted the 2021 IBC and IRC, with amendments. Both codes allow modular or off-site constructed buildings, including steel-framed container units, as long as they meet minimum standards. These include structural integrity, fire resistance, energy efficiency, and egress safety.

Under these codes, container homes must be engineered to withstand specific loads (wind, snow, seismic) based on the location. They must also include proper insulation, smoke detectors, and fire-resistant finishes.

Container homes fall under two primary code designations:

IRC for single-family homes and ADUs

IBC for multifamily, commercial, or industrial structures

The choice between IBC and IRC affects the permit type, review complexity, and inspection stages.

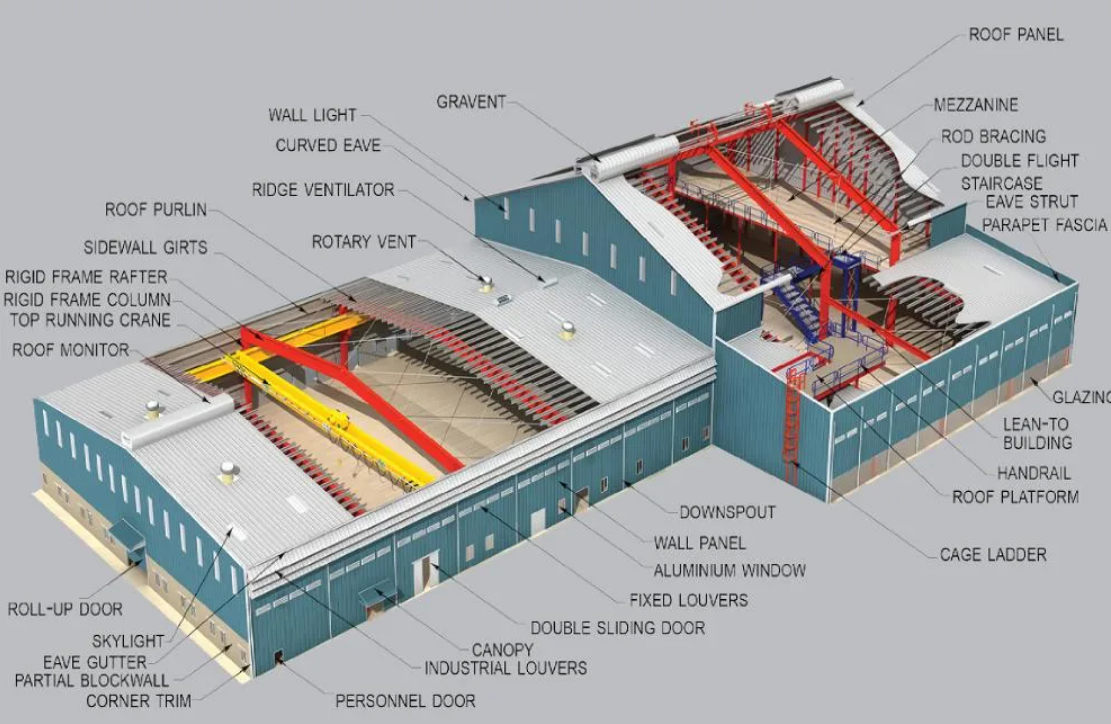

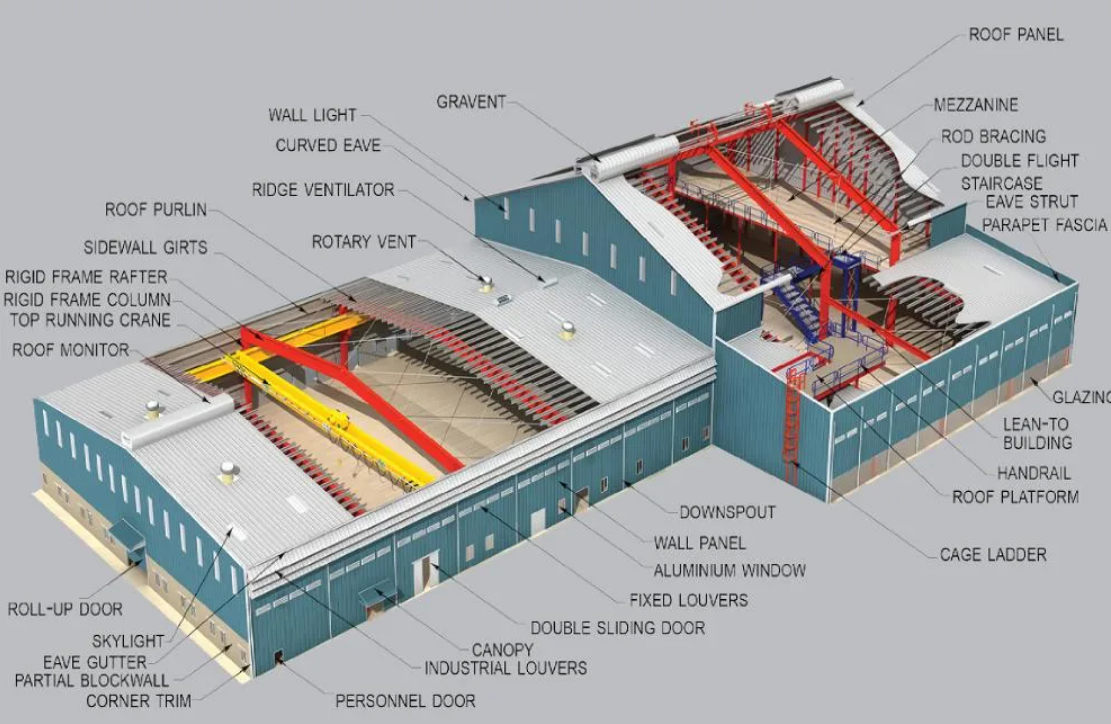

How IBC/IRC Apply to Steel-Frame Modules

In practical terms, container homes must be evaluated for their steel shell’s compatibility with code-mandated performance. This includes:

Structural Compliance: Most shipping containers are strong under compression but need reinforcement when large openings (doors, windows) are cut. Engineering analysis is required to ensure structural stability.

Fire Safety: Steel conducts heat, so adequate fireproofing of the interior (e.g., gypsum board with fire rating) is essential. For multi-unit dwellings, fire separation walls and emergency exits are also required.

Thermal Insulation: Containers must meet the Washington State Energy Code (WSEC). That means sufficient insulation (spray foam or rigid board) with an effective vapor barrier, plus energy-efficient windows and HVAC systems.

Ventilation and Moisture Control: Air exchange systems or mechanical ventilation is required to meet indoor air quality standards.

Using a pre-engineered container module designed specifically for Washington’s building climate, such as those from Yantai Jedha Industrial and Trading Co., Ltd., dramatically improves your chances of approval while speeding up the permitting process.

Municipal Variations

Every city or county in Washington has its own permitting style, timelines, and fees. In some cities, container homes are seen as a progressive solution to housing shortages; in others, the novelty of the structure may invite additional scrutiny. Three prominent examples highlight this variation:

Seattle generally permits container ADUs and DADUs (Detached Accessory Dwelling Units), particularly in residential zones that encourage urban infill. However, Seattle has stringent green building standards and review processes. Expect a permit fee of $5,000–$8,000 for a basic container home, depending on size and features.

Tacoma offers a more flexible and budget-conscious pathway. In zones that allow manufactured housing or modular homes, container units can be approved with relatively modest fees ($2,000–$4,000) and faster reviews. Tacoma’s economic development office has also supported container-based retail and food service units.

Spokane, with its blend of rural and urban landscapes, allows container homes under the same standards as other modular buildings. The city's planning office focuses on fire and structural compliance. Permit fees range between $1,800–$3,500.

Case Study: Container Home Approval in Bellevue

Bellevue, one of Washington’s most development-conscious cities, recently approved a two-container ADU in a residential neighborhood. The project involved stacking two 20-foot units to form a compact, 400-square-foot studio.

After submitting engineered drawings (provided by a certified international supplier), the homeowner secured approval by demonstrating that the structure met all IRC codes for a detached ADU. The containers were retrofitted with R-30 insulation, energy-rated windows, and a solar-ready roof. Despite Bellevue’s complex review environment, the project was approved in less than 75 days.

This case highlights the benefit of working with a supplier who provides engineered code-ready plans and guidance through local review.

Plan Submittal & Inspection Process

To get your container home approved in Washington, you’ll need to prepare and submit a complete plan package. Typical requirements include:

Site Plan: Showing setbacks, utility locations, and foundation layout

Foundation Engineering: Design for either pier, slab, or crawlspace mount

Architectural Drawings: Elevations, floor plans, window/door placement

Structural Calculations: Sealed by a Washington-licensed structural engineer

Energy Compliance Forms: Proof that insulation, HVAC, and lighting meet WSEC

Ventilation Design: As required by IRC or IBC and mechanical codes

Once plans are submitted, most cities will complete a plan check within 4–10 weeks, depending on backlog. After approval, inspections occur at foundation, framing (if applicable), mechanical, electrical, plumbing, and final stages.

Common pitfalls include:

Not using locally licensed engineers

Lack of complete energy documentation

Insufficient foundation anchoring details

Fire separation gaps between stacked modules

Partnering with a vendor experienced in Washington code helps avoid these delays.

Yantai Jedha’s Turnkey Support

Yantai Jedha Industrial and Trading Co., Ltd. specializes in container-based building solutions designed for full compliance with U.S. building codes, including those in Washington State. Their team understands the detailed requirements of both IRC and IBC construction and delivers:

Pre-Engineered Drawings: Each unit includes full architectural and structural plans with optional Washington engineer stamps

Code-Ready Specs: All models are built with code-compliant insulation, electrical rough-ins, and HVAC provisions tailored for Washington’s climate

Local Code Consulting: Jedha’s specialists help navigate permit applications, interpret local codes, and respond to agency requests

Permit Expediting Services: For enterprise and commercial projects, Jedha can manage submittals, track review timelines, and coordinate inspections

Whether you're developing a backyard ADU in Redmond, launching a container café in Olympia, or deploying emergency housing units in Yakima County, Jedha offers scalable, affordable, and fast-deployable solutions.

Conclusion & Next Steps

Yes, Washington does allow container homes—but each project must be tailored to the location’s zoning and the structure’s intended use. The key to success is understanding the differences between state codes and local ordinances, then aligning your design, documentation, and construction methods accordingly. With a container home that meets the International Building or Residential Code and conforms to Washington's amendments, you’re well on your way to approval.

Before you begin your container home journey, follow this basic checklist:

Verify zoning designation of your property

Determine if IRC or IBC applies based on use

Select a container model with pre-engineered specs

Hire a local engineer or use Jedha’s stamped plan sets

Submit a complete permit package with all documentation

Schedule inspections and follow through to occupancy

To streamline your container project and avoid common code pitfalls, explore Yantai Jedha Industrial and Trading Co., Ltd.’s code-ready container solutions. From single-family ADUs to modular offices and emergency shelters, Jedha delivers quality, compliance, and speed—backed by years of global experience and North American code expertise. Reach out today to get started.