JEDHA Metal Steel Frame H Beam Column for Workshop Warehouse Construction

JEDHA steel building manufacturer specializes in metal steel frame H beam columns designed for comprehensive warehouse building projects. Our steel warehouse buildings utilize high-strength steel materials to meet demanding structural requirements across various industrial applications.

The H beam construction employs Q355 high-strength steel specifications for primary structural components. Carbon structural steel Q235 provides cost-effective solutions for secondary framing elements. This dual-material approach optimizes both performance and project economics.

Column specifications feature 100X20X8mm dimensional standards with custom sizing available for specific project requirements. Color customization accommodates architectural preferences and corporate branding needs. Our warehouse structure supplier capabilities support both standard and modified dimensional requests.

Top wall beam configurations integrate with residential and commercial wall structure requirements. Frame components connect seamlessly with steel walkway and floor systems. The modular design enables flexible building layouts and future expansion possibilities.

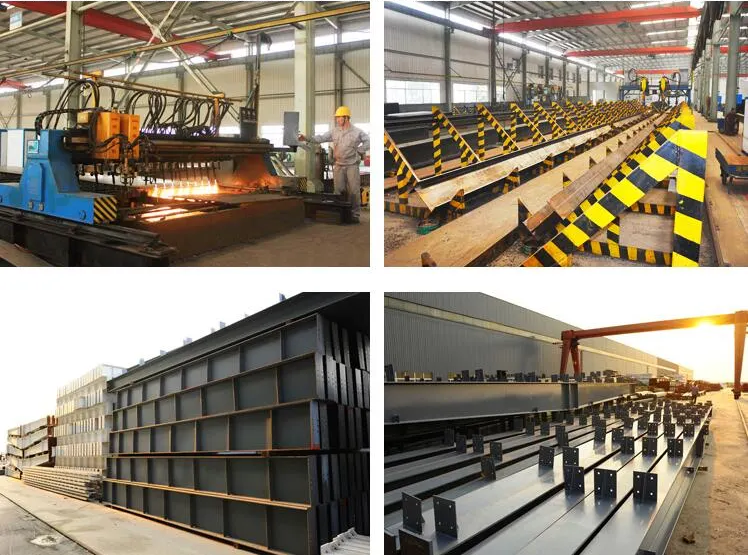

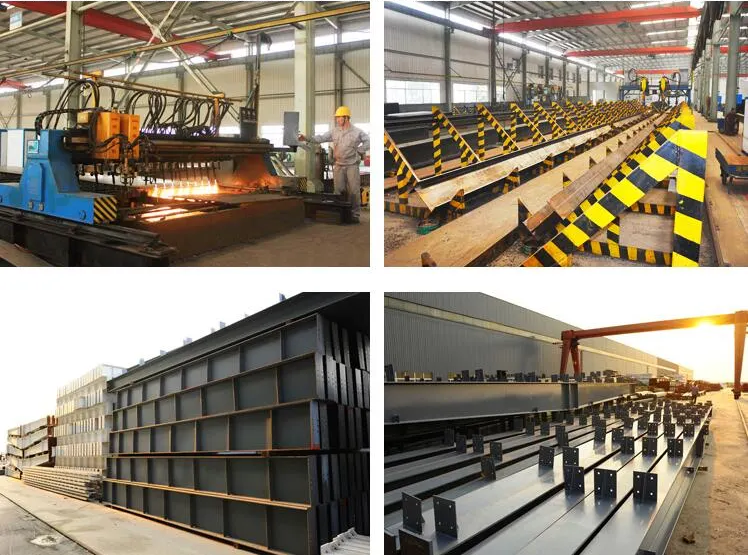

Manufacturing capacity reaches 30,000 tons annually to support large-scale construction projects. Production schedules accommodate urgent delivery requirements and seasonal construction demands. Quality control procedures ensure consistent material properties throughout all product batches.

Industrial steel buildings applications include steel workshop construction, steel structure platforms, and steel fabricated house projects. Structural roofing systems benefit from the H beam's load-bearing capabilities. Steel structure bridge applications utilize these components for heavy-duty infrastructure projects.

Our prefab warehouse construction methodology reduces on-site assembly time by 40-50% compared to traditional building methods. Pre-engineered components arrive ready for installation with minimal field modifications required. This approach minimizes weather delays and labor complications.

Wholesale pricing structures support contractors and developers managing multiple projects. Custom steel warehouse solutions address unique site conditions and operational requirements. Technical support includes structural engineering calculations and connection details.

The 50-year warranty covers material defects and structural performance under normal operating conditions. Sea-worthy packaging protects components during international shipping. Export documentation facilitates customs clearance for global project delivery.

Steel building manufacturer certification includes ISO quality standards and international building code compliance. Material traceability ensures proper steel grades and chemical composition verification. Third-party testing confirms structural properties and dimensional accuracy.

Aircraft hangar construction projects utilize these H beam columns for clear-span requirements. The high-strength steel properties support heavy crane loads and equipment installations. Maintenance schedules remain minimal throughout the building's service life.

Installation procedures require standard construction equipment and certified welding personnel. Connection details accommodate both bolted and welded assembly methods. Field modifications remain possible for site-specific adjustments during construction.

Product Description for Metal Steel Frame H Beam Column Workshop Warehouse Building made of Peb

The commonly followed regulations for designing steel structures are as follows:

- "Steel Design Code" (GB50017-2003)

- "Technical Specifications for Cold-formed Steel Structures" (GB50018-2002)

- "Construction Quality Acceptance of Steel" (GB50205-2001)

- "Technical Specifications for Welded Steel Structures" (JGJ81-2002, J218-2002)

- "Technical Specifications for Steel Structures of Tall Buildings" (JGJ99-98)

The steel structure of a factory, prefabricated building or steel frame building is a pre-engineered construction made of steel. It is extensively used for large-scale workshops, warehouses, supermarkets, entertainment centers, and other types of buildings.

About Us:

Yantai Jedha industrial and Trading Co.,ltd is an expert producer of Prebuilt constructions, Structural system, Metallic sandwich panels, Prebuilt sandwich sheet, Supplementary system, C/Z purlin, and roof ventilation system in China. Our entire range of products has obtained ISO9001: 2000/ ISO14001: 2004 certification.